Cathodic Electro-Phoretic Deposition (CED) Plants

Cathodic electrophoretic deposition (CED), also known as cathodic electrocoating or simply electrocoating, is a coating process used to apply a protective layer of paint or other coatings to a metal substrate. This method is commonly employed in various industries to provide corrosion resistance, enhance appearance, and improve durability of metal parts. CED plants are specifically used in consumer appliance / automotive industry where in the production rate required is very high at a very high levels of quality to be maintained within the required parameters.

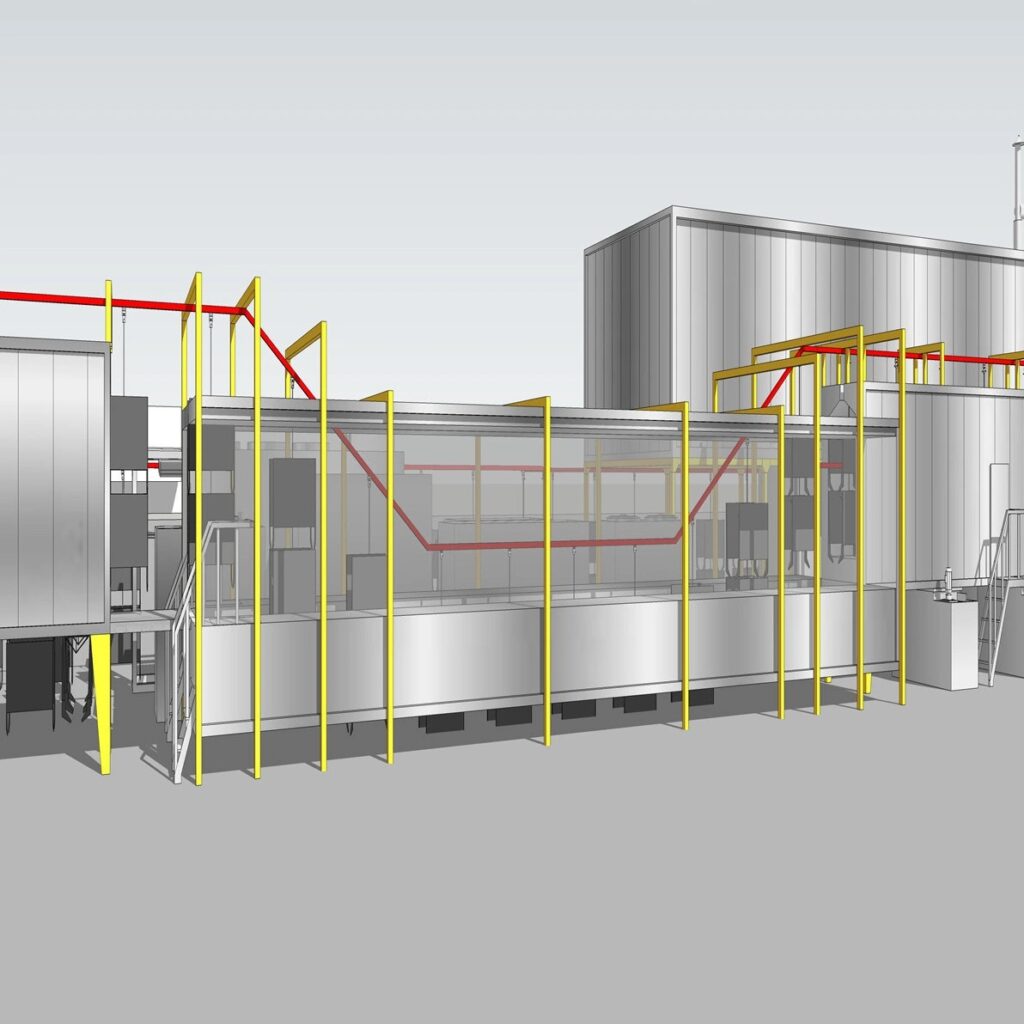

ARIA CED Plants are only available in custom made plants to suit the exact requirement of the client. We undertake site assessment where possible or request information from the client to understand the workshop space, the finish to be achieved and the dimensions and weight of the parts to be coated. When the understanding of the application is achieved our in-house team of draftsman and engineers design your custom CED plant and submit our general arrangement plan for your perusal.

Once the design is approved, we proceed to submit our offer documents for approval. This process takes 2 to 3 weeks and hence these plants are not something that can be ordered from shelf.

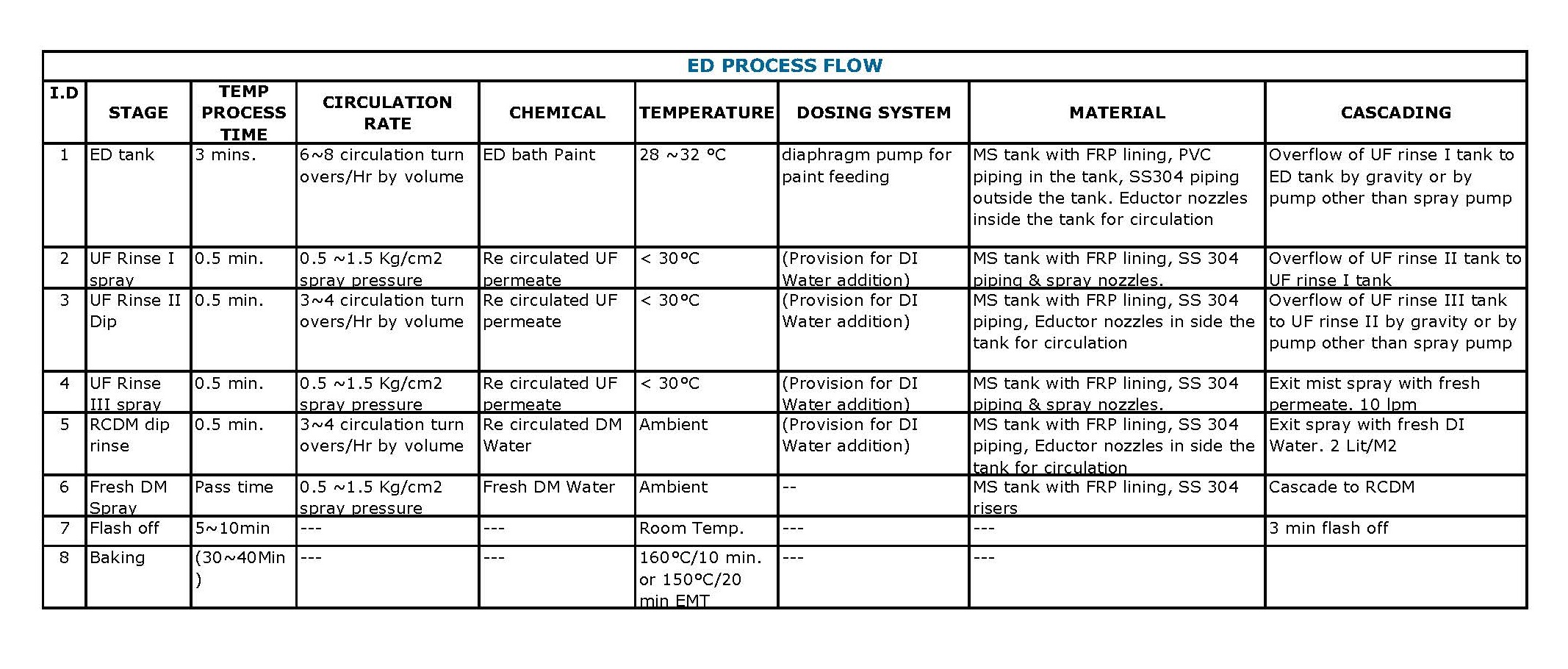

CED Plant Process Stages

Types

ARIA Cathodic Electro-Phoretic Deposition Plants are equipped with automatic spray or dip type pre-treatment process to follow with the electro dipping process. Due to the high volume of production required and different sizes of job parts in the industry these plants are only feasible in custom designed format.

Variations

The process of Cathodic Electro-Phoretic Deposition Plants stays unchanged and requires accurate plant design to achieve efficiency and minimum wastage of valuable consumables. ARIA CED plants have main variations based on construction materials to match budgetary requirements.

The dip tanks required for CED plants can be manufactured with polypropylene, polyethene, PVC, CPVC, FRP or Stainless steel. The materials used for construction of Dip tanks depend on application and the DC current required for bonding as per paint manufacturers specifications.

Construction

ARIA Cathodic Electro-Phoretic Deposition Plants are constructed using 4 mm thick carbon steel, SS 316, SS304 or PVC materials.

The edges of all wall panels are double bent for extra strength. Appropriate bracings and support structure is constructed to maintain structural integrity of the tanks when filled with the paint material to maximum capacity.

As Per CE, ATEX and ISO guidelines all tanks are leak tested and COC is handed over during plant commissioning.

All wall panels are modular in design for easy assembly and disassembly using nuts and bolts.

The construction of all equipment associated with CED Plants is compliant with ATEX, CE and ISO Standards.

Mechanical Equipment

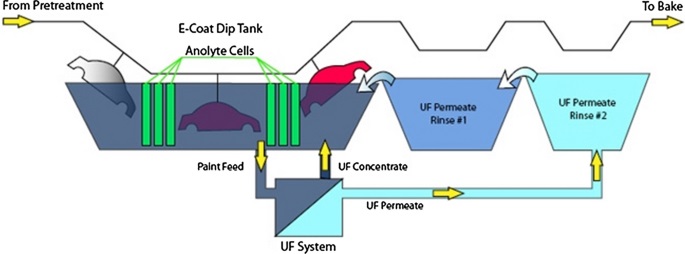

Electrocoating Bath:

The plant includes a tank or bath containing electrocoating material. This material is a water-based paint or coating solution that contains pigments, resins, and additives. The bath is carefully formulated to provide the desired coating properties. ARIA engineers depend on end user feed for the type of electrolyte being used to design and recommend the materials for this bath.

Care is always taken by our engineers to ensure the structure of tanks is adequate to support the weight of the electrolyte.

Immersion System:

The Cathodic Electro-Phoretic Deposition Plants plant is equipped with an immersion system to immerse the parts to be coated into the electrocoating bath. This system ensures that the metal parts are fully and uniformly coated. Immersion systems are usually designed according to job part dimensions and mass as an accessory to be mounted on the material handling system.

ARIA Immersion systems are designed in 2 different types. The shape of the actual conveyor track to lower near the surface of the bath and then inclined upwards to continue the process. The second methos is with the aid of hoist system which halts and dips the job part for the required amount of time.

Rinsing System:

After the electrodeposition process, a rinsing system is used to remove excess coating material and residues from the coated parts. This step is essential for achieving a clean and uniform finish.

Curing Oven:

The Aria curing oven is part of the CED plant where the coated parts are subjected to heat to cure and solidify the deposited coating. The curing process may involve baking the parts at a specific temperature for a defined period.

ARIA curing ovens are described much better on the Curing Ovens Page of this website.

Filtration & Circulation System

In a Cathodic Electrodeposition plant, filtration is an important aspect to ensure the quality and longevity of the Cathodic electrocoating bath. Filtration systems are employed to remove contaminants and particles from the coating solution. The specific types of filters used can vary based on the requirements of the process and the characteristics of the coating material. Here are some common types of filters used in CED plants:

Bag Filters:

Bag filters are commonly used in CED plants to capture larger particles and contaminants. These filters consist of a bag-shaped housing with a porous material that allows the coating solution to pass through while retaining solids. Bag filters are effective in removing coarse particles.

Cartridge Filters:

Cartridge filters are cylindrical filters with a pleated or wound design. They are effective in capturing both large and fine particles. Cartridge filters are used in various filtration stages to achieve different levels of filtration.

Depth Filters:

Depth filters utilize a porous medium with varying densities to trap particles at different depths within the filter media. These filters are effective in capturing a range of particle sizes and offer a higher dirt-holding capacity.

Membrane Filters:

Membrane filters are made of materials with specific pore sizes that allow for precise filtration. They are effective in removing very fine particles and are often used as a final filtration step to ensure a high level of purity in the coating solution.

The electrocoating bath is often divided into two compartments by a semi-permeable membrane. This membrane allows the migration of ions but prevents the mixing of anions and cations. It helps maintain the stability and composition of the coating bath.

Activated Carbon Filters:

Activated carbon filters are used to remove impurities and contaminants, such as organic compounds, from the electrocoating bath. Activated carbon has a high adsorption capacity and can help maintain the quality of the coating solution.

Diatomaceous Earth Filters:

Diatomaceous earth filters use a fine powder made from diatoms (microscopic algae) as a filtering medium. These filters are effective in removing fine particles and can be used in the pre-coat or body feed filtration process.

Sand Filters:

Sand filters are used in some CED plants to remove larger particles. They consist of a bed of sand through which the coating solution passes, and the particles are trapped in the sand bed.

Magnetic Filters:

Magnetic filters can be employed to remove ferrous particles from the coating solution. They use magnets to attract and capture metal contaminants, preventing them from entering the coating bath.

The choice of filters depends on factors such as the size and type of particles to be removed, the volume of the coating solution, and the specific requirements of the coating process. Proper filtration is essential for maintaining the quality of the coating solution, preventing defects in the coated finish, and ensuring the longevity of the electrocoating bath. Regular monitoring and maintenance of the filtration system are important for optimal performance.

Ducting

All ARIA CED Plants come with extraction ducting of 6000 mm for discharge.

Extra ducting required will be charged extra per length.

Ducting is constructed with 1.2 mm thick sheet metal to avoid corrosion and extend life span.

Finishing of ducting is with epoxy-based primer and waterborne topcoat to ensure maximum corrosion resistance.

Environmental, Safety & Interlocks

Effluent Treatment plant:

An effluent treatment system may be included to treat and manage wastewater generated during the coating process, ensuring compliance with environmental regulations. These features collectively contribute to the efficiency, quality, and environmental sustainability of the cathodic electrodeposition process in a CED plant.

Environmental emissions:

ARIA CED plants are designed with appropriate filtration for discharge of fumes into the environment, the fumes generated in this plant are extremely toxic and need to be discarded as per local regulatory bodies.

Safety Interlocks:

ARIA Complete plant systems are designed to foresee risks associated with the complete process and interlocks are established for failures or emergencies to reduce the risk of to the plant area and human life.

Safety features, such as emergency shutdown systems, ventilation systems, and protective measures, are incorporated to ensure the safety of operators and compliance with safety standards.

Energy Efficiency

All ARIA CED Plants have soft start or a VSD for motor control.

All the light fittings used are LED for maximum efficiency.

Optional motion detection sensors can be added to switch off the electrical components when not in use.

Optional Solar panels can be installed to enable the CED Plant to be off grid.

All Fans are designed to give 89% efficiency to reduce electrical consumption.

Curing ovens have the option of oil or gas fired mechanism.

Control System

Manual relay control with overload protection and contactors for all electrical equipment protection is offered on all ARIA model CED Plants.

Depending on client budget all electrical equipment used in our ESPERTO and ULTIMO CED Plants is Siemens, ABB, EATON, Schnieder or equivalent brands.

All Motors on ESPERTO and ULTIMO models of ARIA CED Plants come with variable speed drives for fan motors.

ULTIMO models of CED Plants come equipped with HMI and PLC systems to automate the complete operations of the CED Plant and to monitor essential data like temperature, pressure, current draw, fuel levels etc. from a central location.

Control panels are constructed with IP 55 rating and can withstand dust and light resistance to water.

Optional integration to existing PLC and SCADA system is offered for specific client requirements.

Direct Current (DC) Power Supply:

A DC power supply is an integral part of the CED process. It provides the electrical current needed for cathodic electrodeposition. The metal parts to be coated act as the cathode, attracting and depositing the coating material.

Temperature Control System:

Maintaining a consistent temperature in the electrocoating bath is crucial for achieving the desired coating properties. The CED plant includes a temperature control system to regulate and monitor the bath temperature.

Control and Monitoring Systems:

CED plants are equipped with control and monitoring systems to regulate various parameters such as voltage, current, temperature, and immersion time. These systems help ensure consistency and quality in the coating process.

Site Installation

ARIA Offers complete turnkey solutions for clients not having inhouse maintenance teams to undertake site installations.

Our Site technicians and engineers travel from South Africa or India depending on the location of installations.

All our technicians and engineers are highly skilled and experienced in undertaking CED Plant installation in as little as 4 days depending on the size of the CED Plant.

In case the client budget does not allow for site installation crew we offer a unique method of client providing local technicians and general helpers and ARIA will only send 1 engineer to guide the team to install and commission the CED Plant.

ARIA also offers detailed installation drawings and videos of tricks to install CED Plants for clients to independently install and commission the CED Plant.

The accommodation, food and travel arrangements for any of the above options must be borne by the client as a separate line item on the offer document.

Commissioning

ARIA CED Plants come with complete commissioning documentation required by your local insurance, Fire safety department, Council and regulatory standards of the region.

A Mechanical engineer signed COC will be issued once our in-house engineer commissions the CED Plant.

A master electrician signed COC will be issued once the electrical engineer has tested and found all compliant.

An Emissions certificate will be issued by our in-house team based on the filtration manufacturer third party testing certificate.

A wall panel fire rating certificate will be issued by ARIA in house team based on our fire tests performed in the past and test reports attached as proofs.

Fume proof light fittings certificates or Explosion proof light fittings certificate will be issued as per local mandatory requirements.

Apart from the above certificates CED Plants come with a maintenance checklist and manual for operations and periodic preventative maintenance of your assets.

All the above documentation will be handed over to the client only after full and final payments are settled.

Warranty

All ARIA Manufactured CED Plants come with a 5-year warranty on construction and materials used.

Third-party manufacturer products such as motors, pneumatic cylinders etc. come with third party warranty of 1 year.

Electrical components do not get any warranty and will have to be checked to be in working order before signing off on the plant handover certificate.

The only condition for 5 years warranty on ARIA CED Plants is to purchase all spares and consumables from ARIA, in case a third-party supplier is used for pirate spare parts the warranty stand void.

In case the client does not follow instructions in the manual for preventative maintenance the warranty is void.

In case there is damage to the CED Plant due to human error, act of God and physical damage due to non-changing of filters on time also the warranty will be void.

IASF Technologies India Pvt. Ltd.

ADDRESS: Gat 87/5, Malwadi, Talegaon Chakan Road, Talegaon Dhabade, Maval, Pune, Maharashtra, India 410506

PHONE: +91 8484 92 93 63

ALTERNATE: +91 82630 94819

EMAIL: INFO at ARIAIASF.COM